Service – Process technology

Lean manufacturing

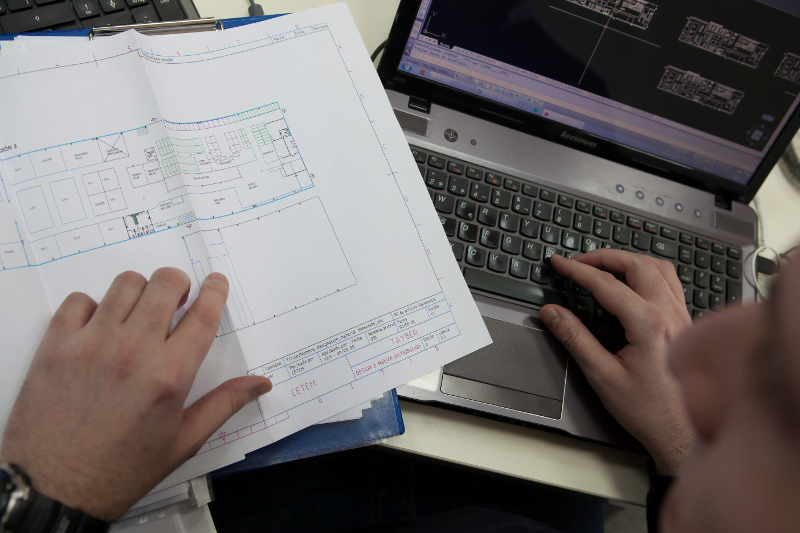

This service aims to increase the capacity of the section or plant where the new distribution will be carried out, ensuring that the workflow fits the daily needs of the company. By applying the 5S, the workplace will feel like home and improvements will last over time.

In addition, all production elements (machines, warehouses, workers, flows) will be optimally distributed so as to obtain maximum efficiency (cost reduction) in manufacturing, based on: space and flow optimisation, reduced displacements, increased production capacity, efficient warehouse management, better working conditions, improved health and safety, steps towards continuous improvement, discipline and corporate culture.

What problem will it solve?

What competitive advantage will the company gain?

What will be delivered to the client?

Questions about this service?